Our Strengths

- Integrated Production

- Low Cost, Highest Quality

- Quick Response and Delivery

- Professional Engineering Team

- From Small Lots to Container Units

- OEM Available

Integrated Production

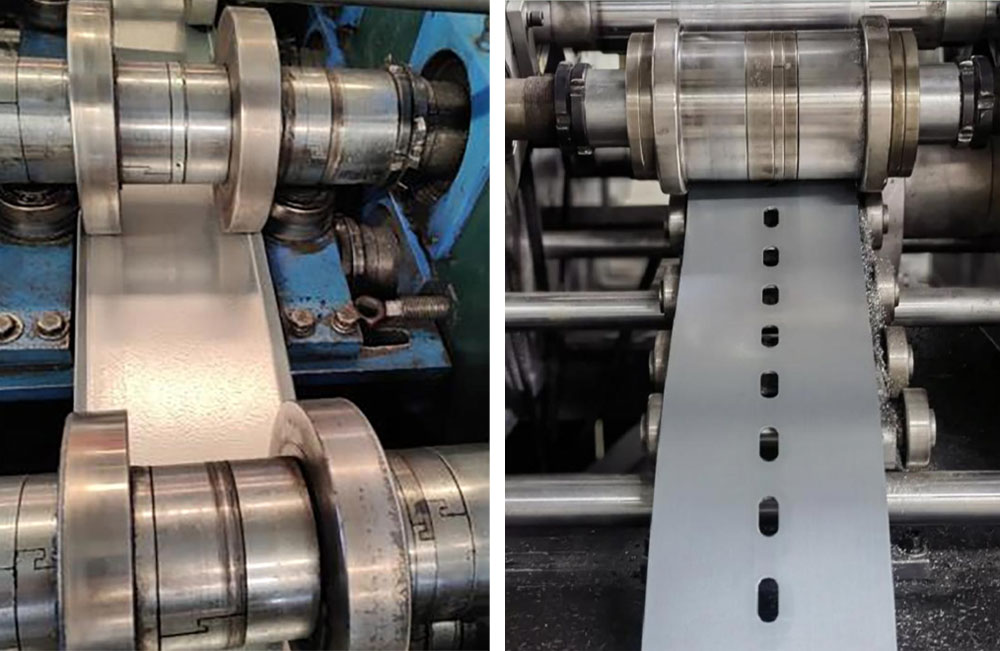

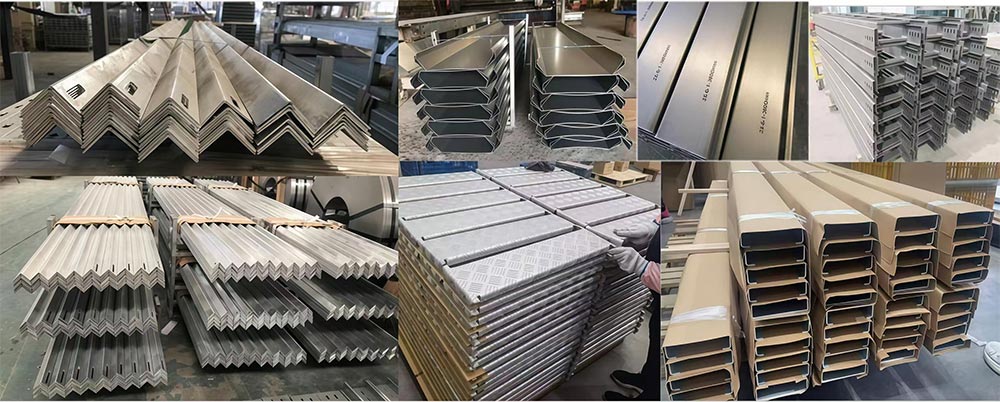

We operate a fully integrated in-house production system, with full control over every stage from material procurement, design, production and processing to inspection, packaging and logistics. Moreover, our factory is equipped with various professional equipment such as cutting, molding, roll forming and punching machines, which can fully meet the needs of production and processing.

Our in-house design team blends market needs and technical feasibility, collaborating closely with production engineers from the start. This optimizes designs for smooth manufacturing, cutting waste and shortening timelines—an edge outsourced design lacks.

Production happens in our well-equipped factory, where advanced machinery and skilled staff ensure uniformity. Automated lines and smart monitoring guarantee every unit (500 or 50,000) meets the same standards. In-house processing (anti-corrosion coating, surface polishing, etc.) avoids third-party handoffs, preventing miscommunication and quality gaps.

Quality is guaranteed via multi-layered inspection: our QA team uses automated tools (for accuracy/safety) and manual checks (for defects/craftsmanship) at key stages—after procurement, during production, post-processing, and pre-packaging. Substandard items are flagged instantly, with fixes made promptly.

What proves our system? Over seven years of exporting to Japan—a market with strict quality demands. We’ve refined processes to exceed Japanese standards for precision and reliability, earning consistent praise from Japanese clients who value our transparency and accountability. For global clients, this means long-lasting products, on-time delivery, and quality backed by a track record in one of the world’s most demanding markets.

Low Cost, Highest Quality

Our commitment to “Low Cost, Highest Quality” isn’t just a slogan—it’s built on strict standards, meticulous process control, and an integrated model that balances excellence with affordability.

Quality starts at the design phase. Every product we develop aligns with JISC89552017—Japan’s rigorous industrial standard that sets high bars for durability, performance, and safety. We also ensure compliance with CE certification, meeting European requirements for health, environmental protection, and consumer safety—so our products work reliably across global markets. To keep quality consistent, we operate under the ISO9001 quality management system, which guides every production step: from material checks to final inspection, each process is documented, monitored, and optimized. No detail is overlooked—whether it’s verifying material purity, calibrating production machines, or testing product functionality—we catch potential issues early to avoid defects.

We also prioritize flexibility, offering customized products tailored to customer needs. Whether it’s adjusting dimensions, modifying materials, or adding specific features, our in-house design and production teams collaborate closely with clients. We listen to their requirements, share technical insights to refine ideas, and turn concepts into tangible products—all while keeping quality standards intact. This personalized approach means clients get exactly what they need, without settling for off-the-shelf solutions.

What makes our “low cost” promise possible? Our end-to-end in-house operations. We handle everything from material procurement to sales directly: we source raw materials from trusted suppliers at competitive rates (cutting out middlemen), produce and process in our own factory (avoiding outsourcing fees), and sell directly to clients (eliminating distributor markups). This integrated model slashes unnecessary costs while letting us control every link—so we can pass savings to customers as factory-direct prices, without sacrificing quality.

For clients, this means more than just affordable products: it’s the confidence of getting items that meet global standards, fit their unique needs, and come at a price that supports their budgets. Whether you’re a business needing bulk orders or a client with specific customization requests, we deliver on both “low cost” and “highest quality”—no compromises.

Quick Response and Delivery

When it comes to global cooperation, “quick response” and “on-time delivery” aren’t just nice-to-haves—they’re critical to keeping your business on track. That’s why we’ve built a system that excels at both, backed by experienced teams and efficient production processes.

Our sales team is the first line of support, and their over 10 years of experience working with overseas customers makes all the difference. They don’t just speak your language—they understand the nuances of international business: from navigating different market demands to addressing cultural communication habits, and even anticipating potential pain points (like customs documentation questions or product specification clarifications). This means when you reach out with an inquiry—whether it’s about product details, pricing, or order status—you won’t get generic replies or long waits. They can quickly grasp your needs, provide accurate information, and even offer practical suggestions (such as adjusting quantities to fit your timeline) in real time.

Beyond quick communication, we deliver on speed when it matters most: production and shipping. Our factory operates with a streamlined workflow, optimized to turn orders into finished products fast—we can ship within two weeks of order placement for most standard products. How do we do this? First, our integrated in-house production system (covering material procurement, processing, and inspection) means we don’t waste time waiting on external suppliers or third-party facilities. We keep key raw materials in stock based on market demand, so once your order is confirmed, we can start production right away. Second, our production team is familiar with balancing speed and quality—they follow strict schedules without cutting corners on inspections, ensuring every product meets our standards while staying on track.

We know that “quick delivery” means nothing if the product isn’t right—or if your urgent needs get overlooked. That’s why our commitment to speed goes hand in hand with attention to detail: when you have a last-minute question about your order’s progress, our team can provide real-time updates; if there’s an unexpected issue (like a rare material delay), we’ll notify you immediately and offer solutions (such as alternative materials or adjusted delivery timelines) to keep your plans on track.

At the end of the day, our goal is simple: to let you focus on your business, not on chasing replies or waiting for shipments. With our experienced sales team handling your inquiries quickly and our factory delivering quality products within two weeks, we turn “quick response and delivery” from a promise into a consistent experience—helping you stay agile and competitive in your market.

Professional Engineering Team

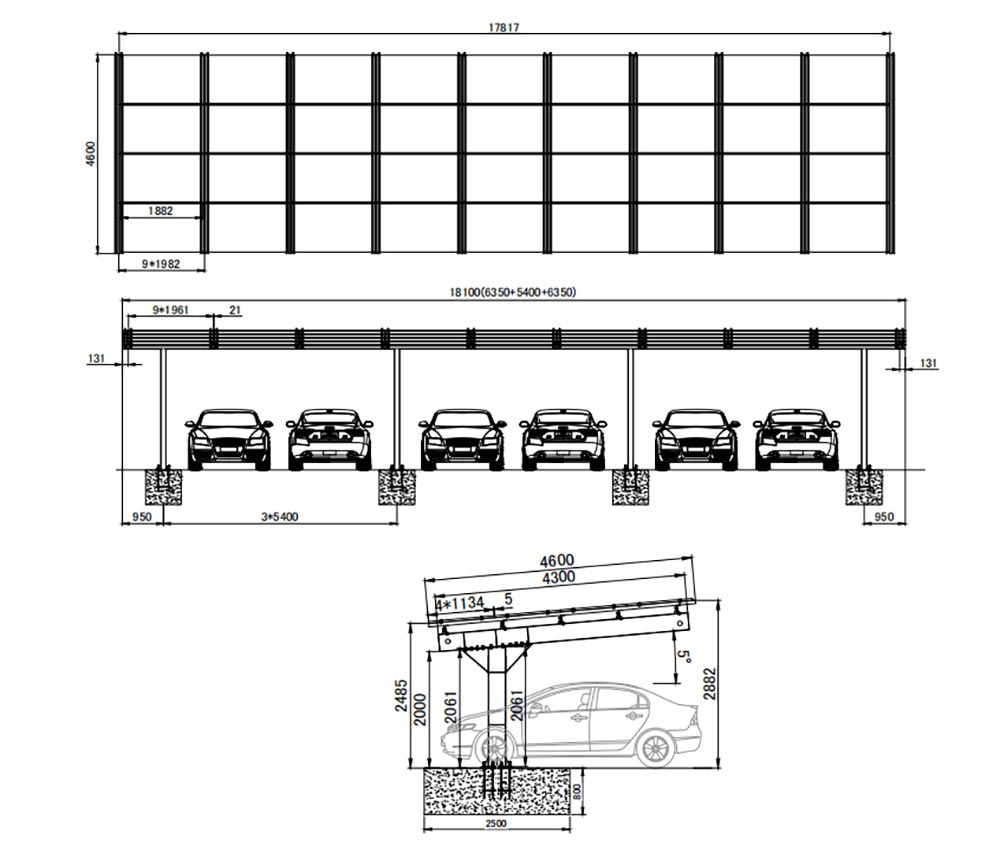

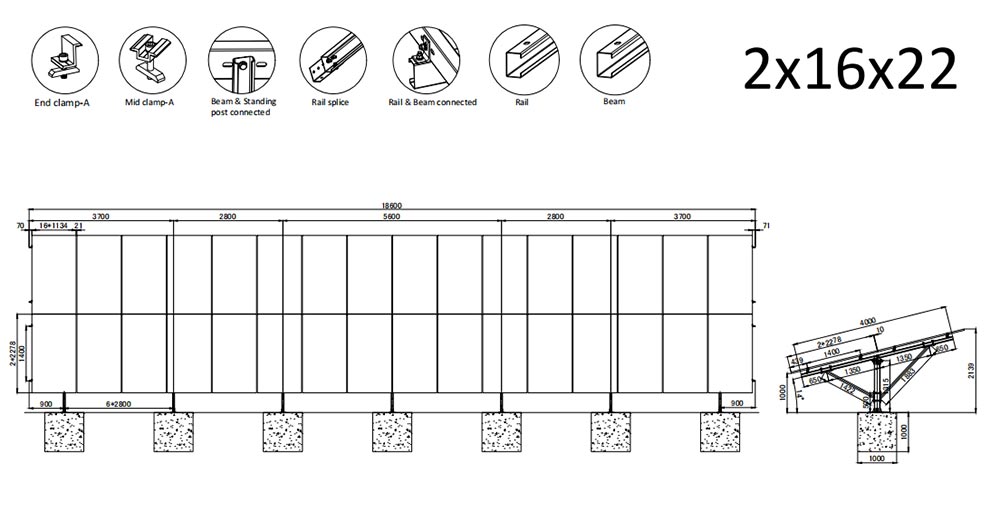

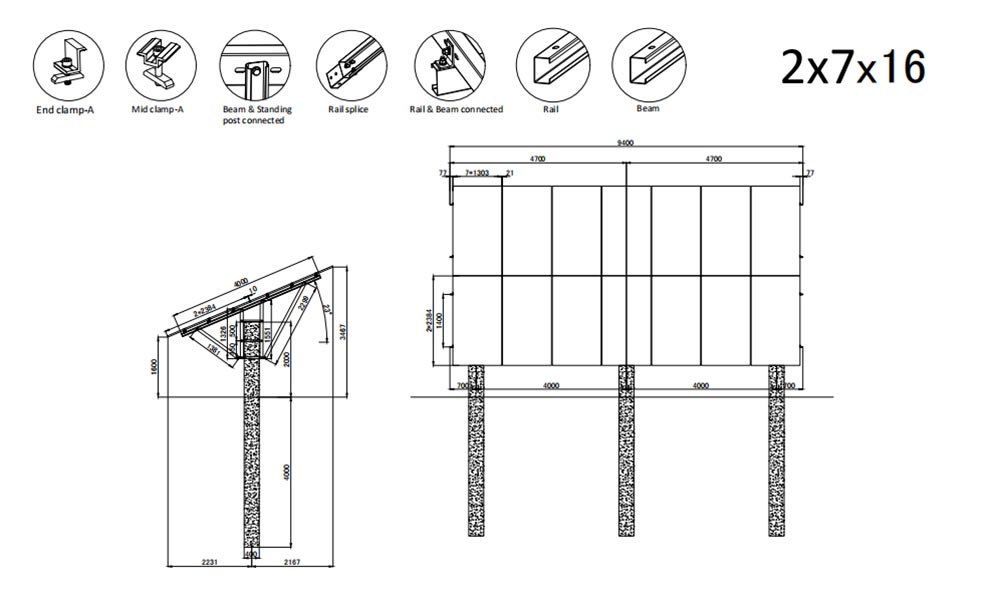

As a solar mounting system specialist, our core technical support is a professional engineering team with an average 10 years of industry experience. These years are not just general accumulation, but precise expertise in the sector—covering rooftop, ground-mounted, agri-solar and fishery-solar mounting designs. The team has in-depth, practical knowledge of key requirements like load-bearing, weather resistance and power efficiency compatibility.

The team’s key strength is efficiently turning customers’ personalized needs into feasible solutions. Whether for irregular sites, improved installation efficiency, or balancing cost and 25+ years of durability, they first clarify core requirements. Then, using technical expertise, they create customized mounting solutions via structural optimization and material selection—meeting expectations and fitting practical scenarios.

When facing challenges posed by complex environments, the team also has mature response experience. For high-altitude low-temperature areas, they adjust the structural joints of mounting systems and select low-temperature-resistant materials to avoid the impact of freeze-thaw expansion on stability. In sandy and windy regions, they optimize surface coatings and connection methods to reduce wear and corrosion. In rainy areas, they design drainage slopes and enhance foundation anti-corrosion measures to ensure the long-term reliable operation of mounting systems.

The team’s services go beyond solution delivery. During the solar mounting installation process, if customers encounter adaptation issues, the team will promptly provide remote guidance or structural adjustment suggestions to resolve installation problems in a timely manner, supporting the stable implementation and long-term use of the solar mounting systems.

From Small Lots to Container Units

Whether you’re a startup testing market demand, a small business with limited storage, or a large enterprise needing bulk shipments, we’ve designed our order system to adapt—seamlessly handling everything from small-lot orders to full container units, with the flexibility to meet even the most specific shipping needs.

For small-lot orders, we never treat them as “afterthoughts.” We know that for many clients—like new brands launching a product line or local retailers stocking niche items—small quantities are a smart, low-risk choice. That’s why we’ve eliminated the “minimum order quantity (MOQ) barriers” that often frustrate small buyers. Our production line is designed to switch between batch sizes efficiently—no long wait times for setup, no hidden fees for smaller runs. And quality never slips: every unit, regardless of order size, goes through the same ISO9001-aligned inspection process. This flexibility lets you test market response, manage cash flow, or meet short-term demands without overcommitting to large inventory.

When it comes to full container units, we leverage our integrated production and logistics system to ensure efficiency and reliability. For large-volume orders—whether you’re restocking a regional warehouse or fulfilling a major retail contract—we start with a customized production plan: our team coordinates with procurement to secure enough raw materials, schedules dedicated production time to avoid delays, and conducts batch-level quality checks to maintain consistency across thousands of units. On the logistics side, we work with trusted freight partners to reserve container space in advance, handle all customs documentation (aligned with global standards like CE and JISC8955:2017), and track the shipment in real time—so you always know where your container is, from our factory to your warehouse. We also optimize loading to maximize container space, reducing per-unit shipping costs and minimizing environmental impact.

At the end of the day, our order flexibility is about putting you in control. We don’t make you fit our system—we adapt our system to fit your business needs. Whether you’re ordering a small batch to test the waters, a full container to scale up, or a mixed load to diversify, we deliver the same level of quality, speed, and transparency—helping you run your business more smoothly, no matter the order size.

OEM Available

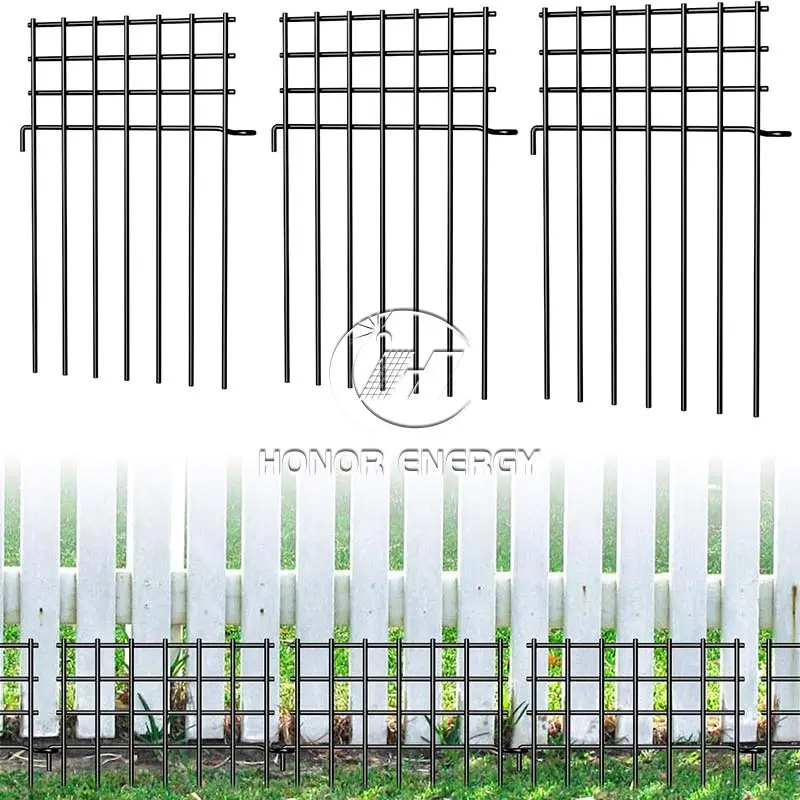

Beyond our ready-made product lineup, we’re proud to offer comprehensive OEM services—meaning we don’t just supply standard items; we can bring your unique ideas to life by turning your custom drawings and requirements into tangible, high-quality products. Whether you have a detailed technical blueprint, a preliminary design sketch, or even just a clear concept of what you need, our team has the expertise and flexibility to make it happen.

The OEM process starts with close collaboration—we don’t just “accept” your drawings; we work with you to refine them for practical production. Our in-house engineering team will review your custom designs carefully, checking for factors like material feasibility, manufacturing efficiency, and compliance with global standards. If we spot potential issues—like a design detail that might be hard to produce at scale, or a material choice that could affect durability—we’ll share constructive feedback and offer alternative solutions, all while keeping your original vision intact.This collaborative approach ensures your design isn’t just “made”—it’s made well, efficiently, and in line with your business goals.

We also adapt to all types of design formats and requirements, whether you’re providing 2D CAD files, 3D models, or even hand-drawn sketches with precise dimensions. Our team is familiar with industry-standard design software, so we can easily import and analyze your files to create a clear production plan. And we don’t limit customization to just appearance or dimensions—we can also tailor product functions.Whether you need a one-of-a-kind prototype for testing or a large batch of OEM products for market launch, we scale our services to match your order size, from small lots to full container units.

Quality control remains a top priority throughout the OEM process, just like with our own products. Every custom-made item goes through the same rigorous ISO9001-aligned inspections: we check materials before production, monitor key manufacturing steps to ensure adherence to your design, and conduct final tests to verify functionality, durability, and compliance. This means you get OEM products that meet the same high standards as our ready-made lineup—no compromises on quality, even for fully customized orders.

For businesses looking to build their own brand or meet niche market needs, our OEM service is a reliable solution. We handle the entire production process, from design review and material sourcing to manufacturing and shipping, so you can focus on marketing, sales, and growing your business. With our technical expertise, flexible production capabilities, and commitment to quality, we turn your custom drawings into products you can be proud to put your name on.