Send Inquiry

Contact Info

-

Address

Xinfeng 3rd Road, Huli District, Xiamen, Fujian Province, China

-

Tel

-

E-mail

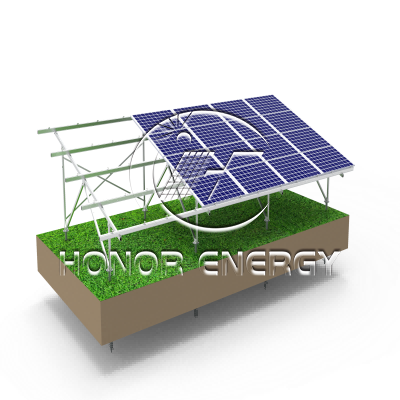

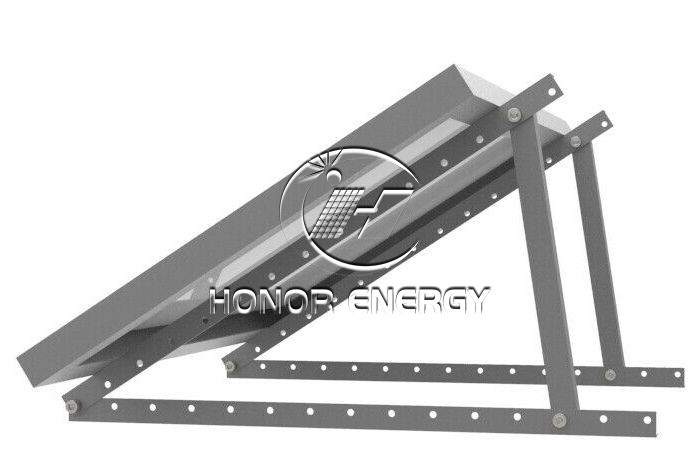

Ready to order? Honor Energy's China factory provides competitive pricing and design feedback for Solar Ground Mount, Solar Roof Mount, Solar Carport Mount, catering to OEM.