Why Choose a Solar Steel Ground Mount for Your Solar Projects?

As solar power continues to expand globally, businesses, landowners, and energy developers are paying closer attention to the reliability and durability of mounting systems. Among the many options, the Solar Steel Ground Mount has become one of the most trusted solutions for medium to large-scale solar installations. This is because it offers strength, flexibility, long service life, and optimized performance even in challenging environmental conditions.

Choosing the right mounting structure is just as critical as selecting high-efficiency solar panels. A poorly designed system could compromise stability, increase maintenance costs, or even shorten the life of the solar array. On the other hand, a well-engineered Solar Steel Ground Mount ensures safety, maximizes energy generation, and reduces total cost of ownership.

In this article, we'll introduce the core features, technical specifications, and advantages of our Solar Steel Ground Mount. We'll also address frequently asked questions to help you make the most informed decision for your next solar project.

Key Features of Solar Steel Ground Mount

-

High Strength and Durability

-

Made from high-grade carbon steel with hot-dip galvanized coating.

-

Corrosion resistance ensures a long service life in harsh climates.

-

Strong enough to support panels under heavy wind and snow loads.

-

-

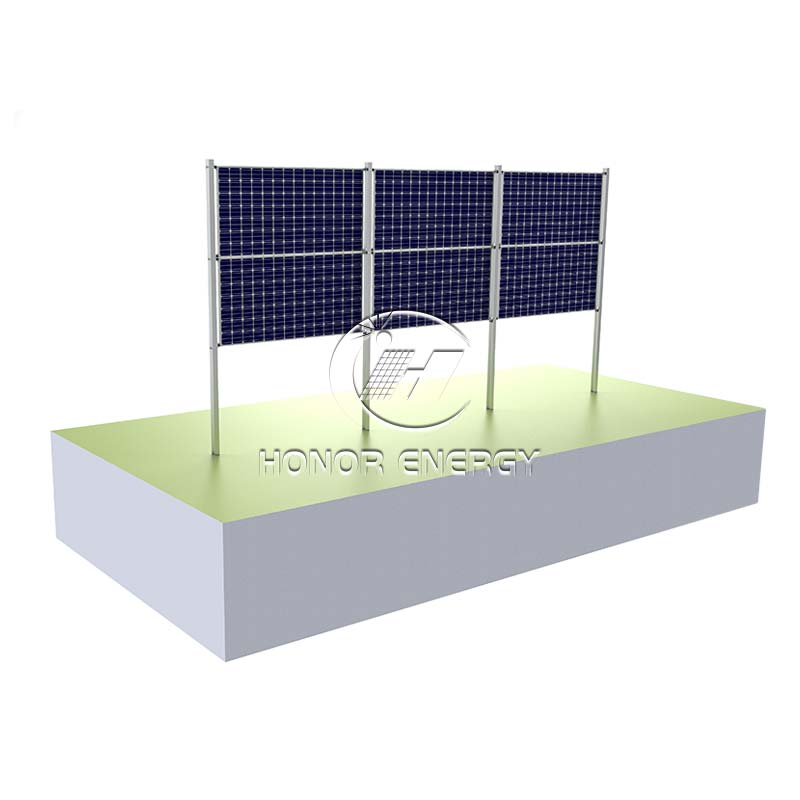

Flexible Design

-

Compatible with framed and frameless solar modules.

-

Adjustable tilt angles to maximize energy generation.

-

Suitable for different terrains including flat land, slope, and sandy soil.

-

-

Easy Installation

-

Pre-assembled components reduce on-site labor.

-

Smart design lowers installation time by up to 40%.

-

Simple screw pile or concrete foundation options.

-

-

Cost-Effective

-

Long service life reduces replacement costs.

-

Lower maintenance needs compared to aluminum alternatives.

-

Provides higher value over the project lifetime.

-

Product Specifications

Below are the core parameters of our Solar Steel Ground Mount system.

| Parameter | Specification |

|---|---|

| Material | Q235B / Q345B Carbon Steel (Hot-Dip Galvanized) |

| Coating Thickness | ≥ 80μm (Standard HDG) |

| Applicable Module Type | Framed or Frameless Solar Modules |

| Module Orientation | Landscape or Portrait |

| Foundation Options | Ground Screw / Concrete Pile / Driven Pile |

| Adjustable Tilt Angle | 5° – 40° (Customizable based on site conditions) |

| Wind Load Resistance | Up to 60 m/s |

| Snow Load Resistance | Up to 1.4 kN/m² |

| Service Life | 25+ Years |

| Warranty | 10 Years Standard |

Advantages of Choosing Solar Steel Ground Mount

-

High Corrosion Resistance: Thanks to hot-dip galvanization, the structure can withstand decades of exposure to extreme environments.

-

Strong Structural Integrity: Engineered for large-scale projects, it offers excellent load-bearing capacity.

-

Wide Compatibility: Suitable for both crystalline and thin-film panels, offering flexibility to developers.

-

Sustainability: 100% recyclable materials align with global sustainability goals.

-

Project Customization: Tailor-made solutions available for utility-scale solar farms.

Xiamen Honor New Energy Technology Co., Ltd. has a strong track record in designing and manufacturing reliable mounting systems that help clients achieve maximum returns on solar investments.

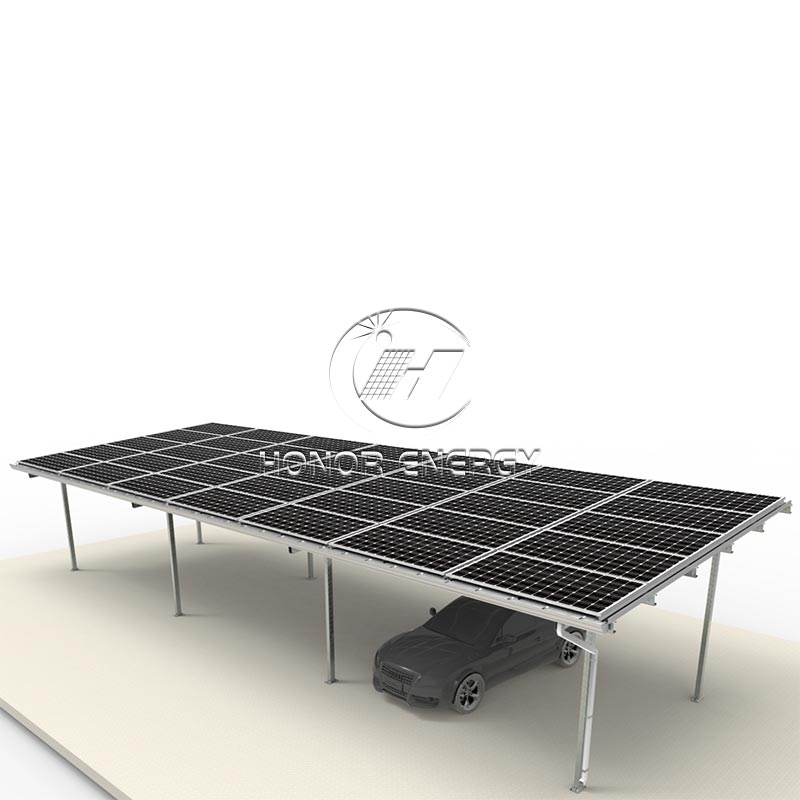

Applications of Solar Steel Ground Mount

-

Utility-Scale Solar Farms

Designed to handle thousands of solar modules with strong wind and snow resistance. -

Commercial Solar Projects

Cost-effective solution for industrial parks, agricultural operations, and commercial lands. -

Challenging Terrains

Flexible design supports installation in sandy deserts, hilly lands, and even snowy regions.

Installation Overview

-

Step 1: Site Preparation

Survey the land and choose the appropriate foundation type. -

Step 2: Foundation Installation

Either screw piles, driven piles, or concrete bases depending on soil condition. -

Step 3: Structure Assembly

Pre-assembled components are bolted together for quick installation. -

Step 4: Module Mounting

Solar panels are secured in either landscape or portrait layout.

This streamlined process minimizes project timelines and ensures faster commissioning.

Frequently Asked Questions about Solar Steel Ground Mount

Q1: What is a Solar Steel Ground Mount and why is it better than aluminum systems?

A Solar Steel Ground Mount is a ground-mounted solar racking system made from high-strength steel. Compared to aluminum systems, steel offers higher structural strength, longer durability, and better performance in large-scale projects. It is particularly advantageous in areas with strong winds or heavy snow.

Q2: How long does a Solar Steel Ground Mount last?

With proper galvanization and anti-corrosion treatment, a Solar Steel Ground Mount can last more than 25 years. The standard warranty offered is 10 years, ensuring long-term peace of mind for investors.

Q3: Is a Solar Steel Ground Mount suitable for all terrains?

Yes. The system can be adapted for flat, sloped, sandy, or rocky terrain. Different foundation options (screw pile, driven pile, or concrete) make it versatile and suitable for varied site conditions.

Q4: How does a Solar Steel Ground Mount contribute to project cost savings?

Its robust structure reduces the risk of damage, lowering maintenance costs. Pre-assembled parts cut installation time, saving labor costs. Over its long service life, it delivers excellent return on investment compared to weaker alternatives.

Why Partner with Xiamen Honor New Energy Technology Co., Ltd.?

-

Over a decade of experience in solar mounting solutions.

-

Professional engineering team providing custom designs.

-

Large-scale production capacity ensuring timely delivery.

-

Global project references across Asia, Europe, and the Americas.

-

Dedicated customer support for technical and after-sales service.

By selecting Solar Steel Ground Mount systems from Xiamen Honor New Energy Technology Co., Ltd., clients gain not only durable products but also a trustworthy long-term partner for their renewable energy journey.

When planning a solar installation, choosing the right mounting system is as crucial as selecting the panels themselves. A Solar Steel Ground Mount ensures reliability, adaptability, and durability, making it the top choice for developers and investors alike.

If you're ready to optimize your next solar project with a professional, cost-effective, and long-lasting solution, contact Xiamen Honor New Energy Technology Co., Ltd. today.

- Tracking Systems: Tech Boosts New Energy

- What Makes a Solar Ground Screw the Best Foundation Solution for Modern Solar Projects?

- PV mounting brackets: from standard parts to project-tailored designs

- A Perfect Fit for Your Roof: Our NEW Roof Cliplock is in Production!

- Solar Mount Daily Maintenance Guide: Keep PV Plants Stable and Extend Mount Service Life

- How Does an Adjustable Solar Roof Mount Maximize Solar Efficiency and Installation Flexibility?