What Makes a Solar Ground Screw the Best Foundation Solution for Modern Solar Projects?

Solar energy installations continue to expand rapidly, and selecting the right foundation system plays a crucial role in the safety, durability, and efficiency of every project. Among all available mounting options, the Solar Ground Screw has become one of the most trusted choices for residential, commercial, and utility-scale solar farms. This guide explains how it works, why it matters, and what makes it an exceptional alternative to traditional concrete foundations.

Before diving deeper, this article will show technical specifications, application advantages, product parameters, and professional FAQs — helping you understand why a Solar Ground Screw is often the top recommendation for ground-mounted solar constructions.

What Is a Solar Ground Screw and How Does It Work?

A Solar Ground Screw is a steel foundation anchor designed to replace concrete in ground-mounted solar projects. Instead of digging, pouring, and curing cement, installers drive the screw directly into the soil using a hydraulic or electric pile driver.

Its helical structure provides excellent holding power, stability, and resistance to environmental forces. This makes it ideal for solar racking systems that require precise alignment and long-term ground support.

How It Works:

-

The screw is driven into the ground vertically.

-

Its threads grip the soil to create immediate load-bearing capacity.

-

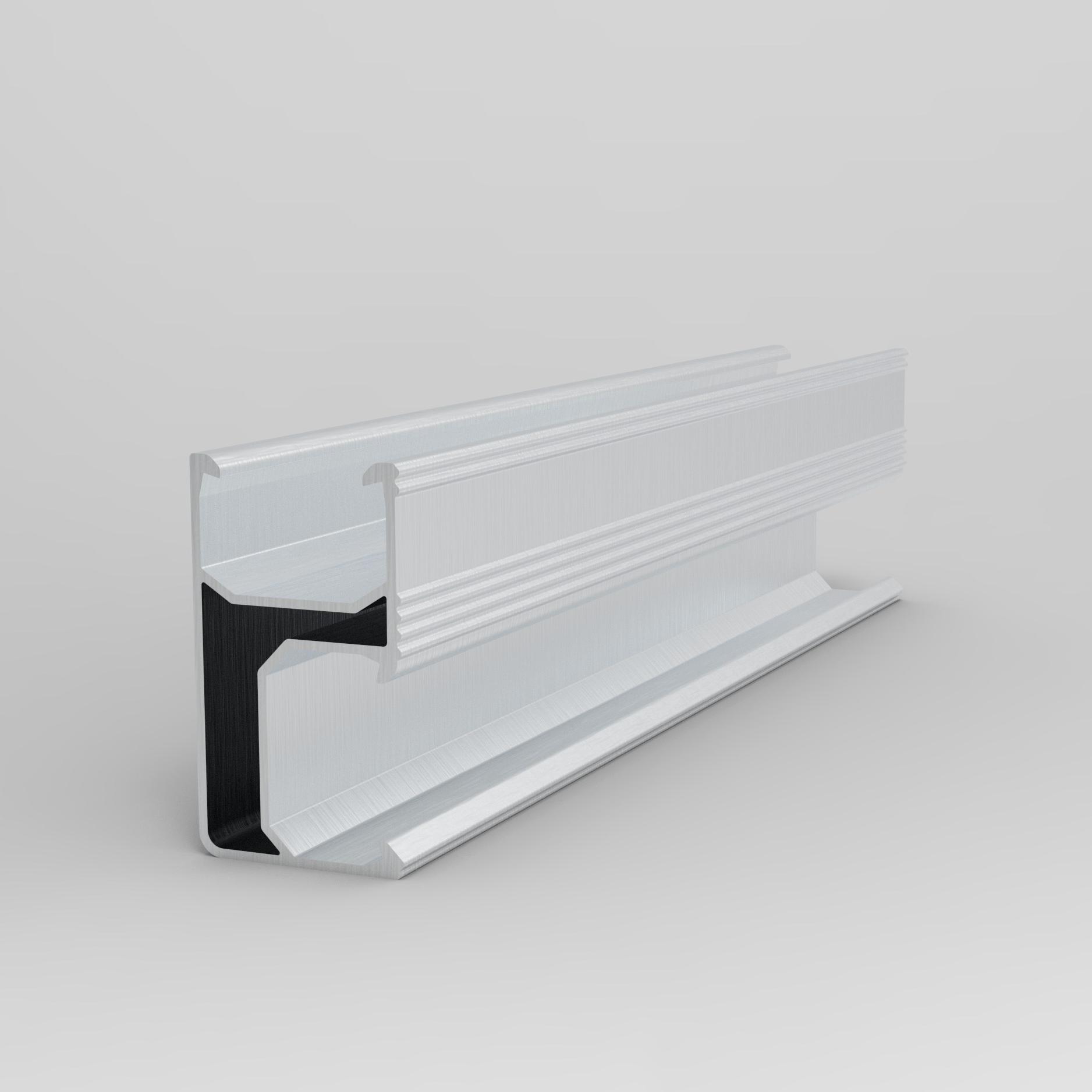

Solar mounting brackets attach directly to the screw head.

-

Frames and panels are fixed on top, forming a stable and durable installation.

Why Choose Solar Ground Screws Over Traditional Concrete Foundations?

The growing popularity of Solar Ground Screws stems from their many practical and engineering benefits. Compared with concrete foundations, they offer faster installations, lower environmental impact, and improved accuracy.

Key Advantages

-

Zero concrete required — cleaner, simpler construction.

-

Immediate load capacity — no curing time.

-

Reusable and removable — ideal for temporary or semi-permanent systems.

-

Compatible with most soil types — sand, clay, gravel, and mixed soils.

-

High vertical and horizontal load capacity — suitable for fixed-tilt and tracking systems.

-

Lower labor and machinery costs.

-

Reduced environmental disturbance.

Which Technical Specifications Define a High-Quality Solar Ground Screw?

Below is a clear, simple table showcasing standard product parameters commonly supplied for solar installations. Specifications can be customized for different soil types, terrain conditions, and project requirements.

Solar Ground Screw Specification Table

| Parameter | Specification |

|---|---|

| Material | Q235 / Q345 carbon steel, hot-dip galvanized |

| Surface Treatment | HDG zinc coating ≥ 80–120 μm for corrosion resistance |

| Length Options | 500 mm – 2500 mm |

| Outer Diameter | 68 mm / 76 mm / 89 mm (custom sizes available) |

| Thickness | 2.5 mm – 4 mm |

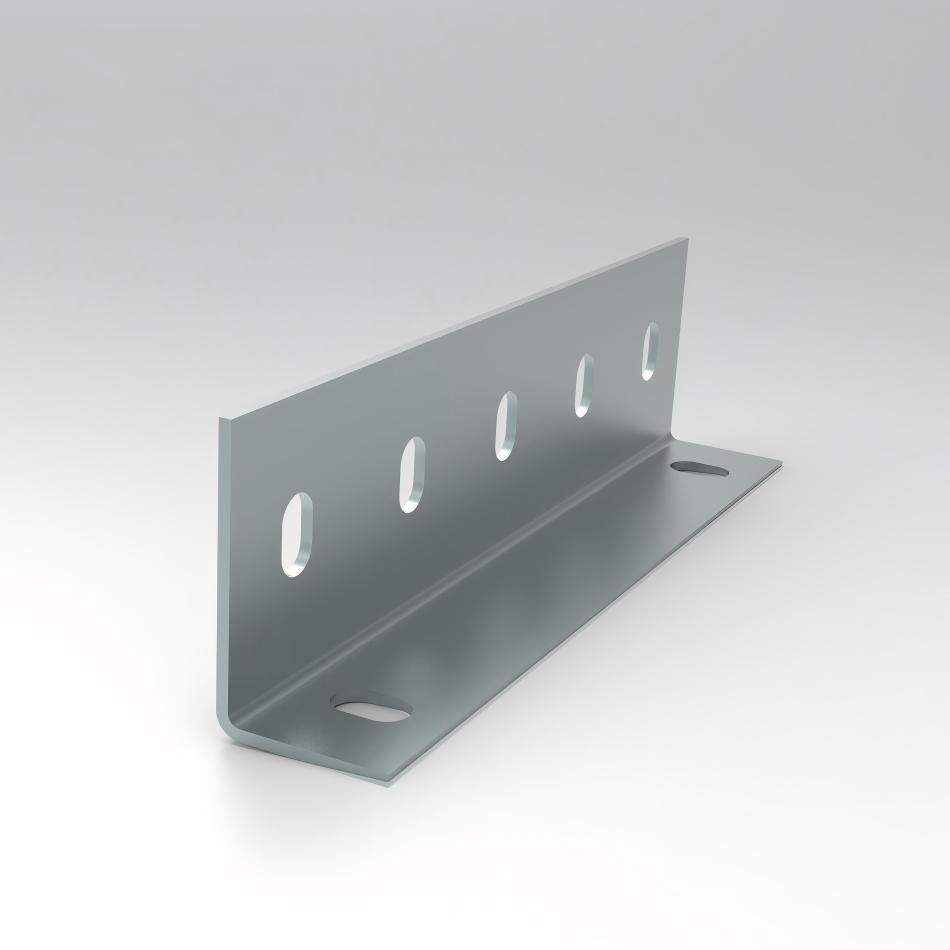

| Flange Types | Round flange, adjustable flange, multi-hole flange |

| Thread Type | Continuous spiral thread for high pull-out strength |

| Installation Method | Electric or hydraulic pile driver |

| Service Life | >25 years under standard conditions |

| Application | Solar farms, carports, agricultural PV, residential ground mounts |

These specifications ensure long-lasting structural performance under various environmental conditions, from coastal regions to rocky inland locations.

How Do Solar Ground Screws Improve Installation Efficiency?

Speed is one of the strongest advantages.

Installation Benefits

-

3–5 times faster than concrete foundations.

-

No excavation — soil remains largely undisturbed.

-

Weather-independent — can be installed in cold or wet environments.

-

Perfect for sloped terrain — adjustable flanges allow precise leveling.

-

Reduced manpower requirements — fewer workers and tools needed.

Because there is no drying or curing period, project timelines can be streamlined significantly, allowing solar developers to operate on tighter schedules and reduce overall costs.

What Are the Main Applications of Solar Ground Screws?

Solar Ground Screws are designed for a wide range of installations:

-

Utility-scale solar farms

-

Agricultural photovoltaic fields (Agri-PV)

-

Residential solar ground mounts

-

Solar carports and parking canopies

-

Off-grid solar systems

-

Temporary or mobile solar structures

-

Terrain with slope or uneven surfaces

Whether the project is small or large, Solar Ground Screws offer flexibility and stability across diverse applications.

Which Factors Should You Consider When Choosing Solar Ground Screws?

To ensure lasting foundation performance, pay attention to:

-

Soil condition — sandy, clayey, rocky, or mixed soil

-

Required loading capacity — horizontal, vertical, and pull-out

-

Project scale and terrain slope

-

Corrosion protection — thickness of galvanization

-

Screw length and diameter based on structural design

-

Torque requirements during installation

-

Compatibility with mounting brackets or racking systems

Professional engineering assessment helps match the right screw type to the project environment.

FAQ: Common Questions About Solar Ground Screw

1. What Makes a Solar Ground Screw More Reliable Than Concrete?

A Solar Ground Screw provides instant structural stability without waiting for concrete to cure. Its hot-dip galvanized steel body resists corrosion for decades, and its helical design ensures strong pull-out resistance even in challenging soil conditions.

2. How Long Does a Solar Ground Screw Last?

With high-quality steel and thick HDG coating, the service life typically exceeds 25 years, making it suitable for long-term solar investments.

3. Can Solar Ground Screws Be Installed in Rocky or Hard Soil?

Yes. Specially reinforced screw designs, pre-drilling methods, and high-torque machinery allow installation in difficult terrains where concrete would require heavy excavation.

4. What Types of Solar Projects Use Solar Ground Screws Most Often?

They are widely used in large solar farms, commercial solar carports, hybrid agricultural fields, and residential ground-mount systems due to their durability and installation efficiency.

Why Solar Ground Screws Are the Smart Foundation Choice

The Solar Ground Screw is transforming solar project construction, offering faster installation, long-term stability, and cost-effective performance across all types of terrain. Its durability, environmental benefits, and compatibility with modern solar structures make it one of the most dependable solutions available today.

For professional Solar Ground Screw solutions, customized specifications, and engineering support, please contact us at Xiamen Honor New Energy Technology Co., Ltd.

-

- PV mounting brackets: from standard parts to project-tailored designs

- A Perfect Fit for Your Roof: Our NEW Roof Cliplock is in Production!

- Solar Mount Daily Maintenance Guide: Keep PV Plants Stable and Extend Mount Service Life

- How Does an Adjustable Solar Roof Mount Maximize Solar Efficiency and Installation Flexibility?

- What Maintenance is Required For a Solar Fence?

- What Are the Weather Resistance Specifications of a Solar Fence?