Material of solar ground bracket

The materials of solar ground brackets mainly include aluminum alloy, stainless steel, carbon steel, hot-dip galvanized, galvanized aluminum magnesium, weather resistant steel, etc.

Material Classification

Aluminum alloy: lightweight, corrosion-resistant, but with low load-bearing capacity, mostly used for roofs of civil buildings.

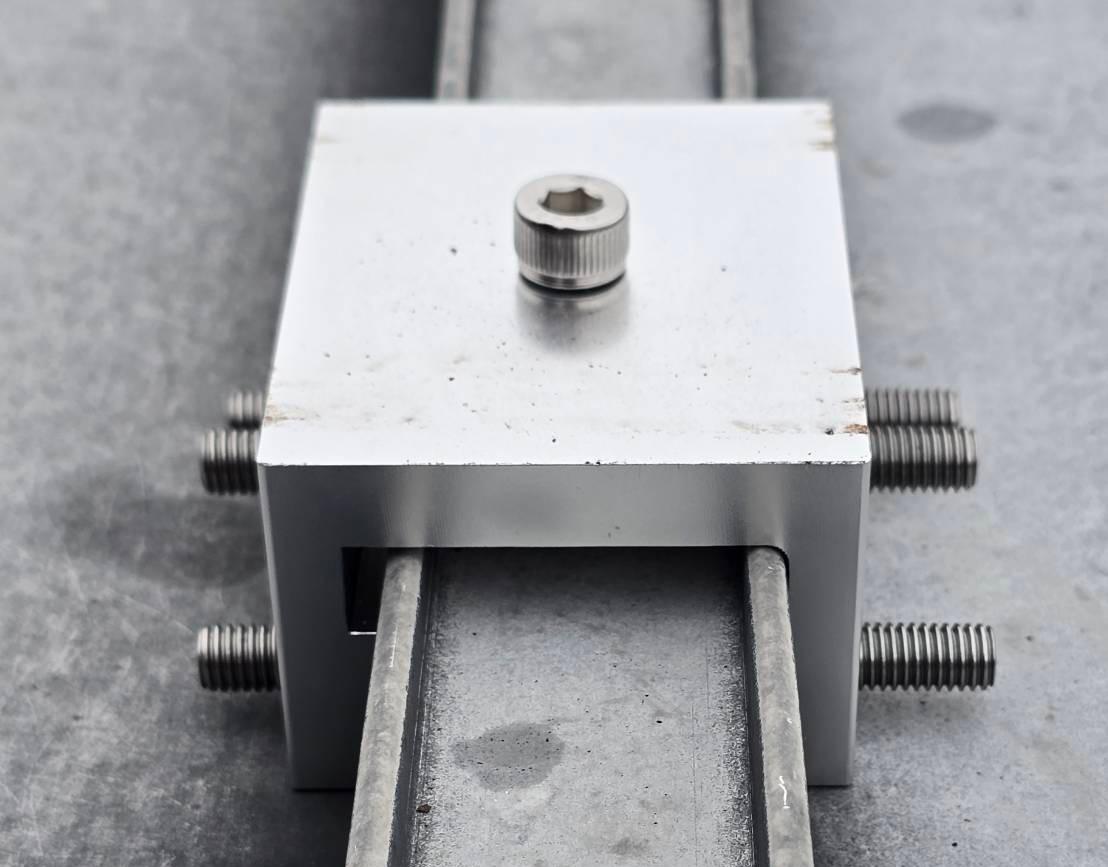

Stainless steel: Excellent anti-corrosion performance, surface treated with anodizing or anti-corrosion treatment, with a service life of up to 20 years.

Carbon steel: surface treated with hot-dip galvanizing, can be used outdoors for 30 years without rusting, has high bearing capacity, and is widely used in ground power stations.

Hot dip galvanizing: a traditional anti-corrosion process suitable for windy areas, with a thickness of up to 2.5mm

Galvanized aluminum magnesium: alloy sheet, resistant to chlor alkali corrosion, suitable for harsh environments such as deserts and saline alkali land.

Weathering steel: With excellent mechanical properties and corrosion resistance 2-8 times that of carbon steel, it has a rust colored appearance and is maintenance free.

Material Selection

In windy areas, carbon steel brackets (thickness ≥ 2mm) or galvanized aluminum magnesium brackets are recommended.

Conventional regions: Aluminum alloy or stainless steel brackets offer higher cost-effectiveness.

Long term maintenance free requirement: Weather resistant steel brackets are more suitable.

-

- Tracking Systems: Tech Boosts New Energy

- What Makes a Solar Ground Screw the Best Foundation Solution for Modern Solar Projects?

- PV mounting brackets: from standard parts to project-tailored designs

- A Perfect Fit for Your Roof: Our NEW Roof Cliplock is in Production!

- Solar Mount Daily Maintenance Guide: Keep PV Plants Stable and Extend Mount Service Life

- How Does an Adjustable Solar Roof Mount Maximize Solar Efficiency and Installation Flexibility?